- HOME

- CDMO Services

- Packaging

Packaging

Based on our abundant knowledge and experieces and development of innovative technologies,

diversity of solutions which meet our costomers's needs will be provided.

One Stop Service

We support from oral formulation and injectables for Investigational medicinal product and commercial manufacturing.

Innovation

We provide various solutions such as environmentally friendly biomass polyethylene packaging.

Regulation

We support to meet the regulatory directives of each country regarding pharmaceutical package labeling and materials.

Packaging Development

We design primary and secondary packaging to match the formulation after a thorough analysis of characteristics of the formulation and usage environment. We also provide packaging design to reduce environmental loading and packaging process design for commercialization and its validation. We leverage all of our knowledge, technologies and experience in pharmaceutical packaging development to meet your needs.

and Usage Environment

・Formulation Characteristics: dosage form, property, and stability

・Usage situation: efficacy and effect, direction for use and dosage (how patients take the medication) etc.

・Solid Formulation: Plastic blister, aluminum blister, bottle, Sachet etc.

・Injectables: vial, ampule, pre-filled syringe, bag etc.

・Eye Drop, nasal drop, external use formulation: bottle, tube etc.

・Protection of formulation: moisture-proof packaging, gas barrier packaging, light-proof packaging, cushioned packaging etc.

・Improvement for Ease of Use: easy opening aluminum bag packaging, card type packaging to enhance medication adherence etc.

・Environmental Considerations: container and packaging that use biomass polyethylene or mechanically recycled PET etc.

・Stability testing of drug product

・Preparation of documents for NDA

・Respond to matters of inquiries from authorities

・Establish packaging material standards and product standards

・Package labeling design (artwork)

・Packaging process design, qualification and validation

Investigational Medicinal Product Packaging

With packaging specifications and packaging process to match the characteristics of the developed compound and clinical trial schedule, we assist in delivering high quality Investigational medicinal product in a timely manner.

Primary and secondary packaging of any formulation including high potent drug substances

Packaging Form

Solid Formulation: Plastic blister, aluminum blister, bottle, Sachet, etc.

Injectables: vial, ampule, pre-filled syringe, bag etc.

Eye Drop, Nasal Drop, External Use Formulation: bottle, tube etc.

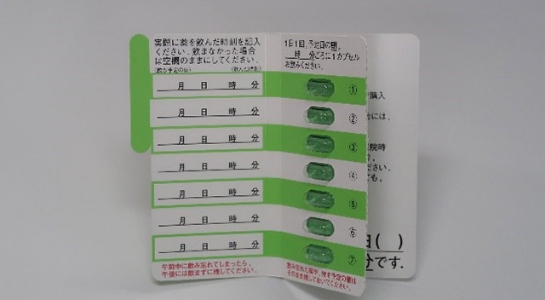

Card Packaging and Wallet packaging for Superior Medication Adherence

Wallet Packaging

Card/Wallet Packaging Equipment

Non-heated type of sealing decreases heat load on the drug product

Masking Technology

Assignment Work

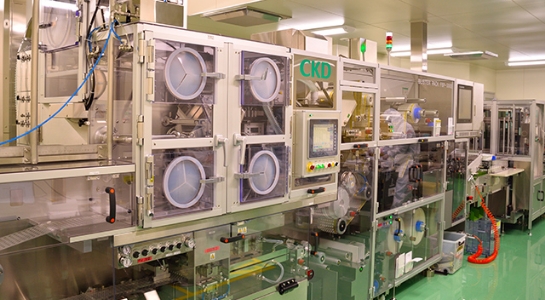

Commercial Packaging

GMP compliant operational system architected and organized with "Safety / Quality /Cost / Environment" included as our basic principle, we provide high quality pharmaceutical packaging.

Various types of product packaging that make use of our experience

Packaging of high potent drug substances

Blister packaging machine (containment type)

Pharmaceutical packaging for global markets

Organized serialization system for the US and China markets

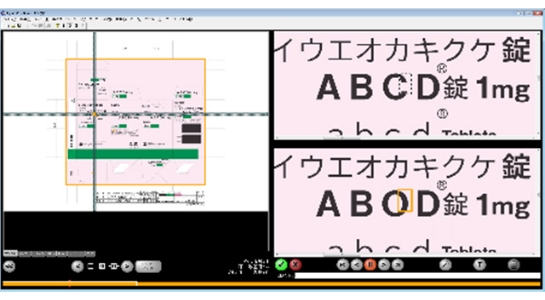

Quality assurance of labeling contents using digital proofreading system

Digital proofreading system

Packaging Lines

General Drugs Solid Oral Formulation (Settsu Plant)

Blister Packaging Line

Capable of handling aluminum blister pack

Assurance of content quality by X-ray inspection

High speed machines packing at 6,000 tablets/min.

Sachet Packaging Line

Bottle Packaging Line

Hormone formulation Injectables and eye drop formulation (Settsu Plant)

Eye Drop Packaging Line

Ampule Packaging Line

Carbapenem Antibiotics Aseptic Powder Filling Formulation (Kanegasaki Plant)

Vial Packaging Line

Cephem Antibiotics Solid Oral Formulation (Kanegasaki Plant)

Bottle Packaging Line (fine Granule)

Bottle Packaging Line (tablet)

Sachet Packaging Line (fine granule and granule)

Blister packaging Line (capsule/tablet)

Printing machine for carton (GS1 variable code) machine

Not high potent injectables (Itamai Plant)

Vial packaging line

Ampoule inspection and packaging line

High potent injectables (Itami Plant)

Vial packaging line (shrink labeler)

Packaging Technology

We provide packaging technology to contribute to improving productivity in order to maximize the value of products.

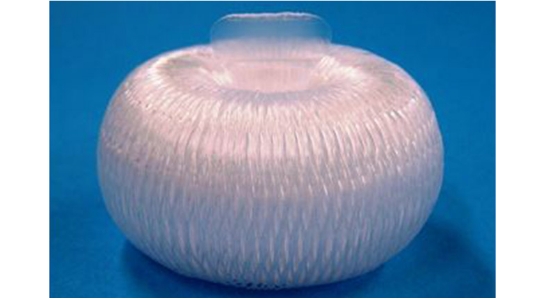

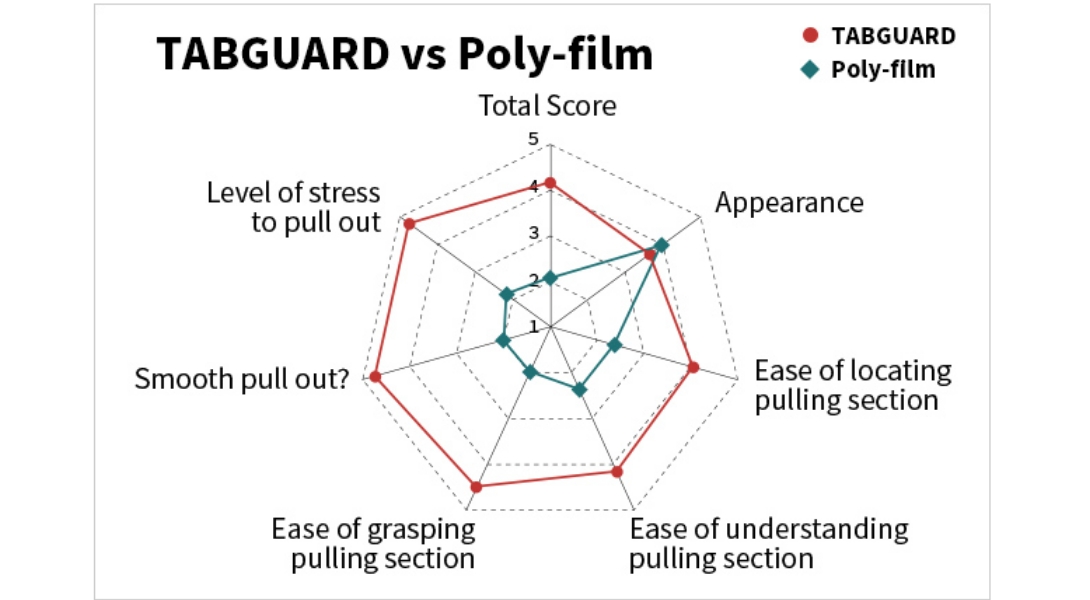

Bottle cushioning packaging material TABGUARD

TABGUARD organoleptic evaluation results

Aluminum tube that allows both high quality protective function and

environmental loading reduction (patented)

Ampule anti-rolling label (patented)

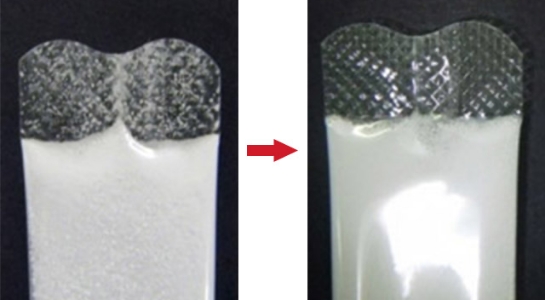

Sachet packaging equipment for precise filling by controlling powder sticking to sealing location (patented)

Sachet packaging equipment suited for fine granule / designed with

mechanism for dust collection concurrently with filling

Solves the issue of powder sticking at sealing locations. Stable filling

volume and improved yield

Technical Support

Our technical support can help resolve issues such as packaging design of new drugs and packaging quality and change controls after commercial introduction.

- ・Technical support for container and packaging design and packaging process design

- ・Technical support for qualification and validation of packaging and shipping

- ・Technical support for improving packaging quality and productivity in manufacturing plants